Wholesale inventory management can be complex. It can be your company’s best friend or biggest downfall.

When you do it right, you’re setting yourself up for consistent business growth. But when you’re unorganized or under-optimized, it can be a downright disaster.

That’s why this article is loaded with inventory management tips and top inventory management techniques to help make sure your business is in the “growth” category and not “disaster.”

We’re going to look at what inventory management is and why it’s so important, some tips to make sure your wholesale inventory system is fully optimized, and some of the best tech you can use to streamline the process.

What is wholesale inventory management?

Wholesale inventory management is the system you use to get, store, sell, and deliver products to your customers. The best wholesale inventory management systems are reliably accurate in their predictions of the store’s demand.

The importance of inventory management in a wholesale business

When you can predict which items customers will buy and when, you’re able to match your inventory count. This means that you won’t have an excess of inventory that ends up losing value or going to waste. You also won’t have too little inventory, causing you to run out of stock and lose customers to your competitors.

It’s possible to make these predictions with good ol’ fashioned math calculations and Excel spreadsheets, but there’s a much easier way to do it: technology platforms and tools.

Now that you understand the basics of wholesale inventory management, let’s look at some tips you can implement in your business for smooth sailing.

Benefits of wholesale inventory management

Better cash flow

Inventory, along with accounts receivable and accounts payable, have tied up $1.1 trillion in cash, which is equivalent to approximately 7% of the United States GDP, according to the latest stats.

Maintaining an optimal level of inventory allows businesses to maintain cash flow, which is vital for reinvestment and growth. With inventory management software, wholesalers keep an optimal level of stock, so they don’t have to sit on unsold goods. This frees up cash for other investments like marketing.

Accurate forecasting

The volume of stock held by manufacturershas doubled, without overall business activity rising in step. Accurate forecasting helps businesses make informed purchasing decisions and prepare for peak periods with effective wholesale inventory management.

Using past sales data and inventory management tools, wholesale distributors can forecast demand for seasonal items like winter coats. With this, they can make well-informed purchases, avoid overstocking, and meet customer demands.

Higher customer satisfaction

With the right amount of stock, orders are fulfilled accurately and on time, which leads to repeat business and better customer relationships. Say a food wholesaler makes sure their restaurant clients have the right amount of stock so they can meet their demands. Fulfilling orders on time and accurately leads to repeat business.

Better cost management

As of 2022, a square foot of a warehouse and distribution center in the United States costs about $7.96. The purpose of wholesale inventory management is to reduce carrying costs, which include storage, insurance, and handling charges. By optimizing inventory levels, you can minimize warehousing expenses and excess inventory costs.

Best wholesale inventory management software picks

So many of your inventory management problems can be fixed with great tech. As mentioned earlier, good wholesale inventory software can save you some major headaches and help to ensure that important tasks and details don’t slip through the cracks.

Even if you don’t have a huge budget for super-sophisticated automation software, there are plenty of tools available to help ease the burden of manual wholesale inventory management.

Let’s look at some holistic tools to help you on your way that won’t break the bank.

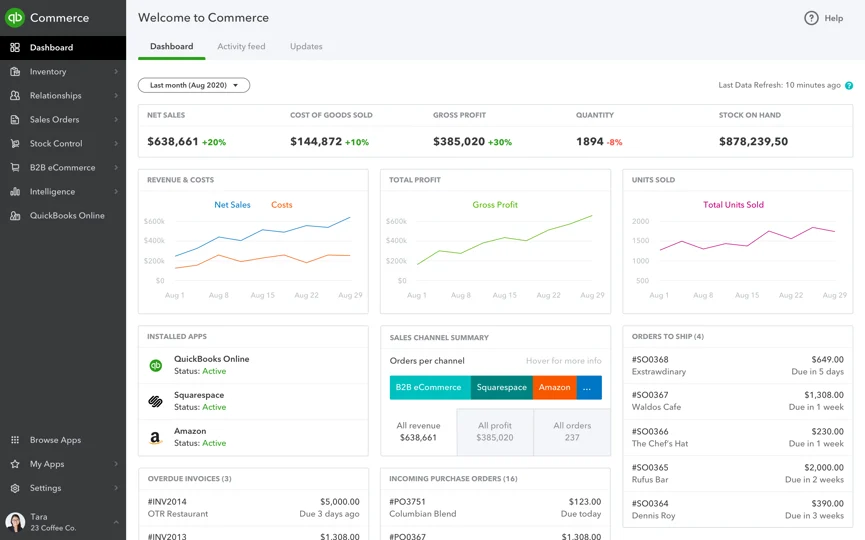

1. QuickBooks Commerce

Source: QuickBooks Commerce

Formerly TradeGecko, QuickBooks Commerce is a holistic wholesale inventory management solution for helping to run, automate, and optimize several aspects of your business. QuickBooks is more geared toward small to mid-sized businesses, and lets you manage multiple channels, track sales, and integration with various ecommerce and shipping platforms.

Pros:

-

Customizable inventory reports

-

User-friendly interface

-

Many integration options

Pricing:

-

Plus: $45 per month

-

Advanced: $100 per month

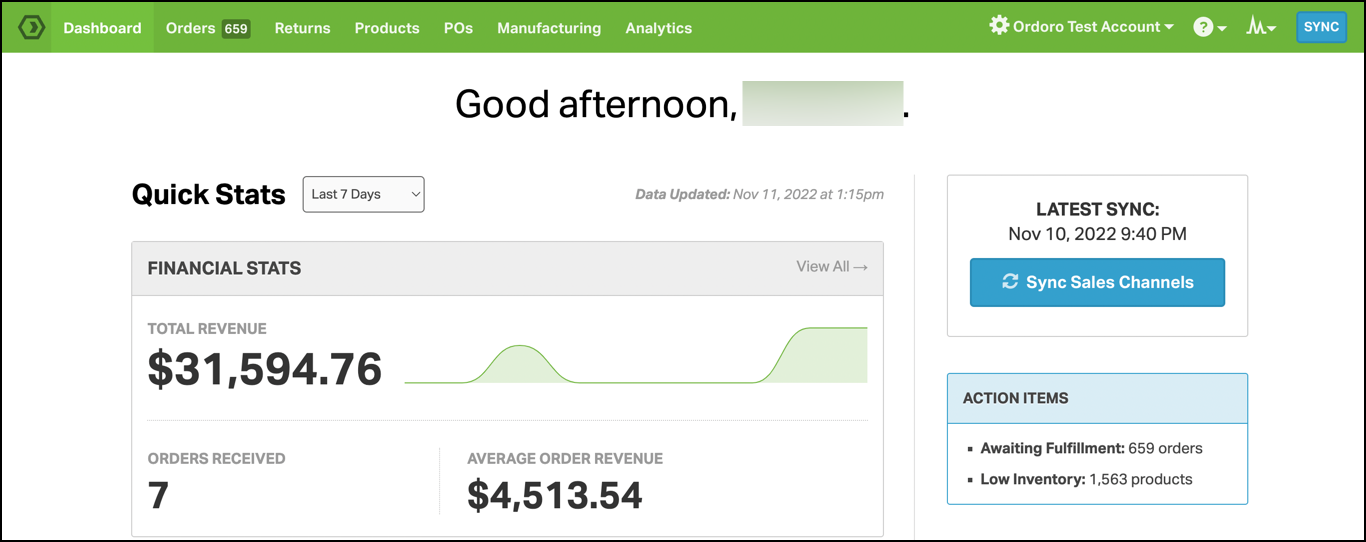

2. Ordoro

Source: Ordoro

Ordoro is another holistic wholesale inventory software. It describes itself as “a control center for all matters inventory,” helping you to manage inventory and ship orders from all of your business’s sales channels.

Ordoro is often praised for its customer service and offers an easy-to-use dashboard with valuable features for inventory management like detail reporting, customer profiling, and discounted shipping rates.

Pros:

-

Dropshipping features

-

Multichannel sales

-

Excellent customer service

Pricing:

Ordoro has a free plan. Paid plans start at $59 per month. For complete inventory management, kitting, dropshipping, RMAs, and vendor portals, you’ll need the Premium plan, which comes in at $149 per month.

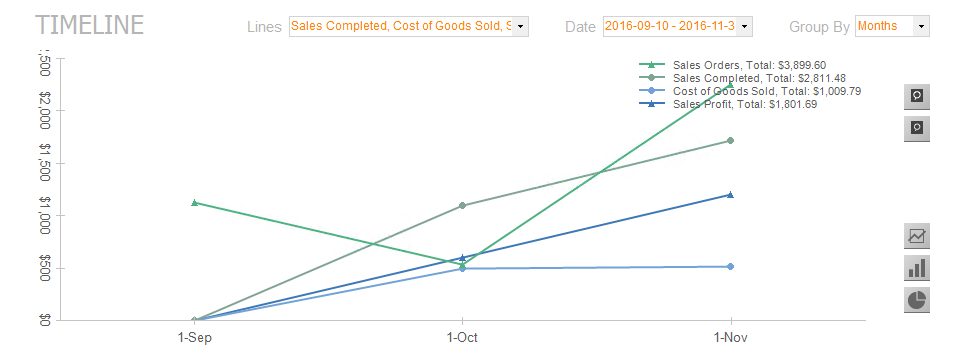

3. inFlow

Source: inFlow

inFlow is a full-service tool that helps with inventory, sales, purchasing, reports, and more. The company even offers a Smart Scanner, a handy custom Android smartphone with a built-in laser scanner that helps you handle inventory management steps, wherever you are.

Pros:

-

Offline access

-

Affordable

-

Versatile for wholesale users

Pricing:

Free 14-day trial. Paid plans are as follows:

-

Entrepreneur: $89 per month, billed annually. Best for one location and 100 sales orders per month.

-

Small business: $219 per month, billed annually. Best for unlimited inventory locations and 1,000 sales orders per month.

-

Mid-size: $439 per month, billed annually. Best for unlimited inventory locations and 5,000 sales orders per month.

-

Enterprise: $1,055 per month, billed annually. Best for unlimited inventory locations and 10,000 sales orders per month.

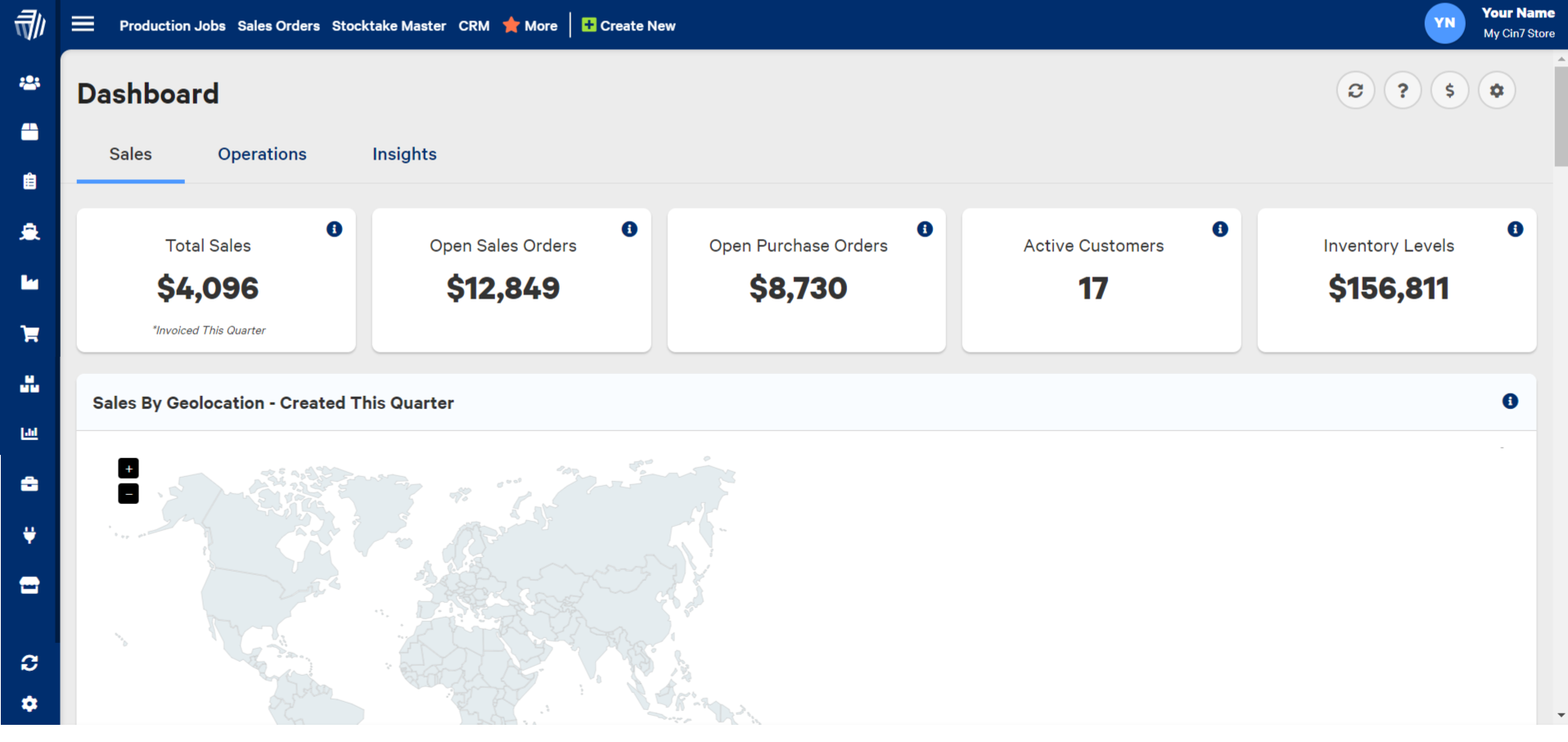

4. Cin7

Source: Cin7

Cin7 is an inventory management solution that’s well-regarded for its extensive feature set and ease of integration with other systems. With Cin7, you can track stock in real time and have automatic cross channel syncing so all sales channels have the latest inventory information. You also get access to features like job cards and inventory added to jobs.

Pros:

-

Ease of use

-

Value for money

-

Customizable reporting

Pricing:

Cin7 offers several pricing tiers, starting at $349 per month for the Standard plan. The Pro plan is priced at $599 per month and the Advanced plan at $999 per month. For the Omni plan, contact Cin7 for pricing details.

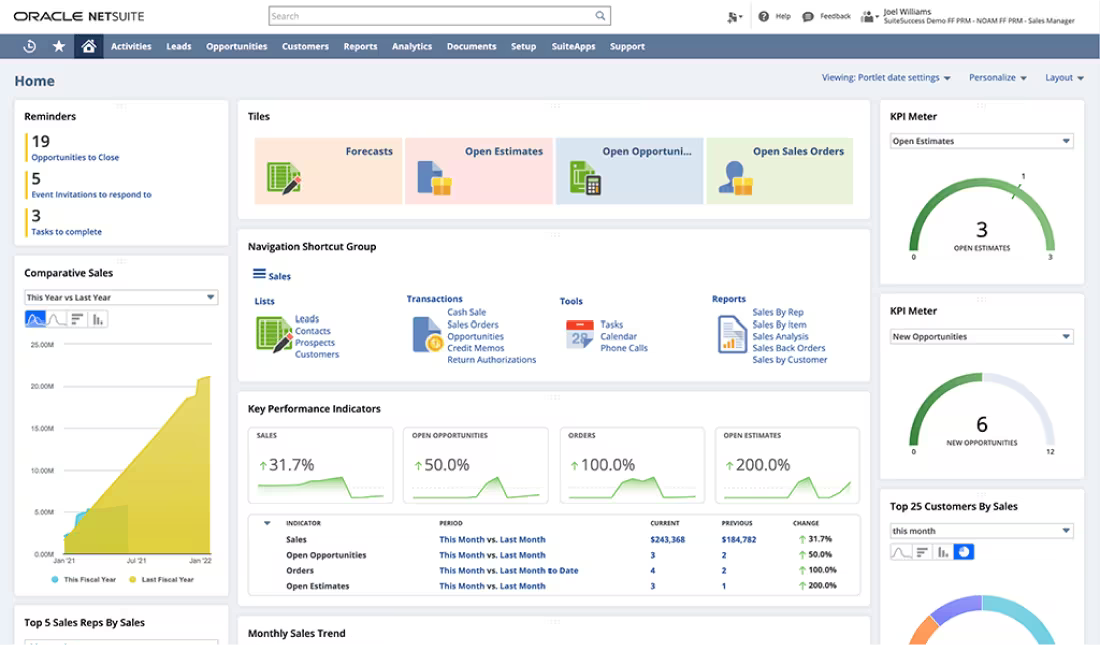

5. NetSuite

Source: NetSuite

NetSuite is another popular inventory management platform for wholesalers. It has comprehensive fulfillment controls to reduce cycle times and shipping costs, while increasing on-time delivery rates. You can also access real-time customer data and real-time financial and accounting insights, like picking accuracy to improve efficiencies.

Pros:

-

High customization

-

Centralized data

-

Scalable

Pricing:

Depending on who you talk to, the total price of implementing NetSuite can range from $10,000 to $100,000 or more. Total costs include a base charge, per user charge, and fees for add-on modules and services.

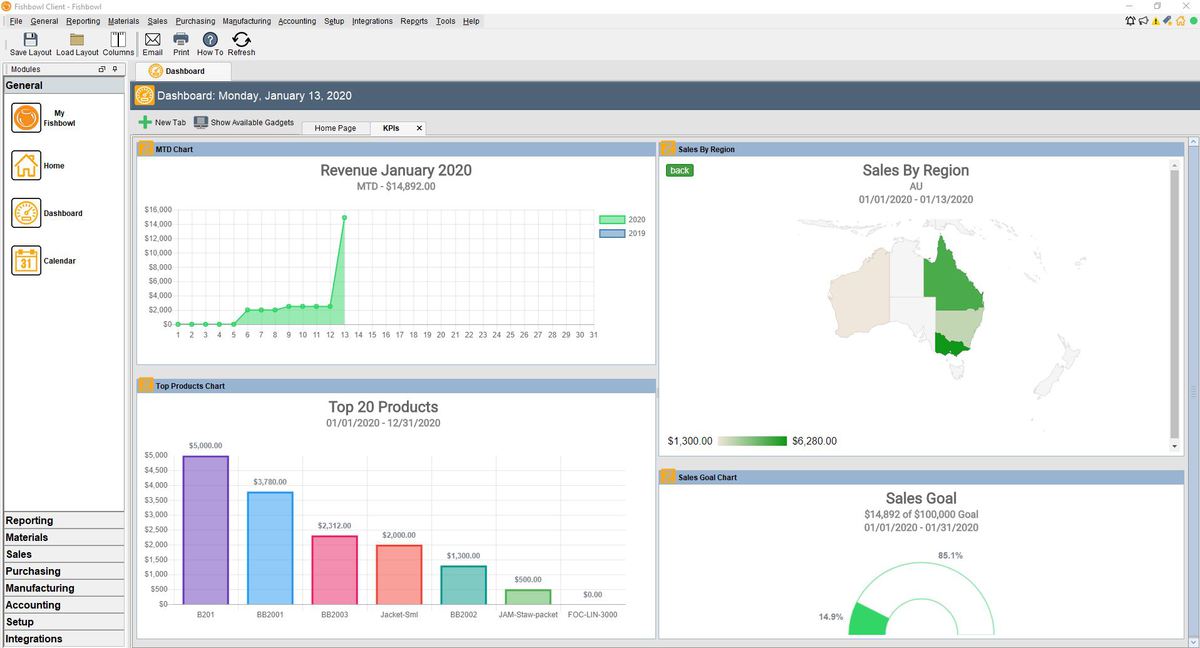

6. Fishbowl

Source: Fishbowl

Fishbowl is a comprehensive, affordable solution for wholesalers looking to manage their inventory more efficiently. With its seamless integration with QuickBooks, this system helps you manage orders, keep track of inventory, and optimize warehouse processes.

Pros:

-

Seamless integration with QuickBooks

-

Advanced inventory tracking

-

Customizable reporting

Pricing:

Fishbowl offers a cloud-based solution as well as on-premises solution with hosted capabilities. Both start at $329 per month for warehousing brands.

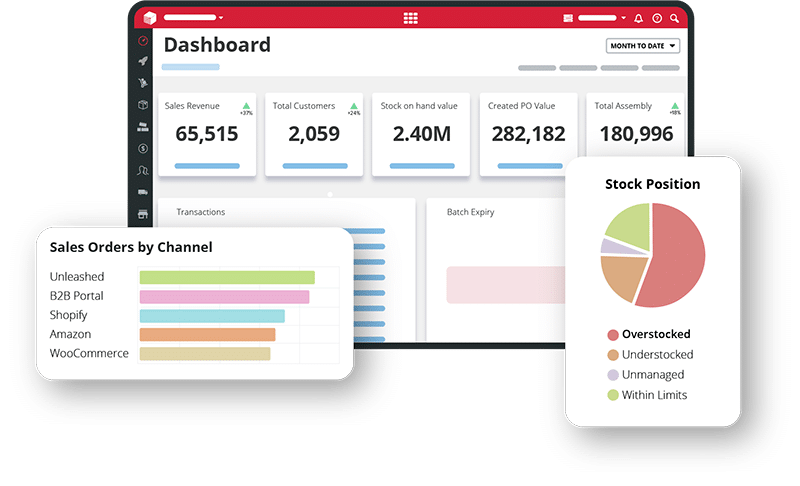

7. Unleashed

Source: Unleashed Software

Unleashed helps wholesalers make data-driven business decisions and manage their stock in real time. Wholesalers looking to stay competitive in the market use Unleashed because it gives a clear picture of inventory levels, supply needs, and sales patterns.

Pros:

-

Batch and serial number tracking

-

Real-time inventory control

-

Powerful reporting tools

Pricing:

Unleashed has three pricing plans:

-

Mid-sized businesses: $349 per month. Best for 1 to 5 users.

-

Scaling businesses: $649 per month. Best for 6 to 12 users.

-

Emerging enterprises: $999 per month. Best for more than 12 users.

Six smart inventory management techniques

1. Try to avoid manual spreadsheet tracking

This is a contentious topic in the wholesale world. Back in the old days, keeping an Excel spreadsheet (or physical documents) was the most popular wholesale inventory system.

Manual techniques will work, but only for a short time. You’ll find that as your store grows, manual inventory management will become harder and harder, to the point where it becomes impossible to keep up.

That’s why it’s best to avoid manual tracking altogether and go straight for software when you’re starting out. Of course, this might be tough for budget or other reasons.

If you’re in this boat, start with manual tracking, but set a hard transition point for when you’ll switch to wholesale inventory software. For example, when you make $10,000 in revenue, you might be more comfortable reinvesting some of it into good software. Just make sure you set a goal and stick to it, or you might be tempted to wait too long—at which point your manual tracking can get really messy.

2. Automate as much as possible

When you grow, a lot of things will fall through the cracks. It usually starts with small things that snowball into big things. Automation is the number one way to make sure this doesn’t happen.

There’s no room for human error, mistakes, or oversights when your wholesale inventory system is built with tools and tech. You don’t have to make sure someone remembers to add your returns back into your inventory count every week. Or make sure the spreadsheet is updated with the seven fields that change after one new entry.

There are tools that can help you automate so much of your operations, like:

-

Tracking your inventory in one or more warehouses

-

Fulfillment operations

-

Delivering customer orders

-

Synchronizing your inventory and orders data across multiple sales channels

-

Reordering your stock at the right time based on automated forecasting calculations

3. Keep track with cycle counting

Keeping an accurate count of your wholesale inventory is crucial. For some companies, this means counting their entire warehouse once a year (or more).

However, cycle counting lets you save yourself a lot of headaches. It also helps you keep track of items on a regular basis, if you need to. Cycle counting works by segmenting your inventory, then creating a schedule so different items and locations in your warehouse are counted every day.

One popular way to categorize your inventory is by using the ABC classification. Here’s how it works:

-

A items are high-value or high-volume items that don’t cost a lot or take up too much space in your warehouse. You might count these more often than others, like on a quarterly basis.

-

B items turn over regularly but have higher costs than A items. You might count them twice a year.

-

C items account for the rest of your inventory. They have the lowest turnover and the smallest impact on your bottom line. You might count them once a year.

4. Aim to minimize your on-hand inventory

In an ideal world, you always have the right amount of inventory. Unfortunately, even with the latest technological advancements, you still can’t predict the future.

When you run out of stock, it’s tough. But on the flip side, it can also be damaging to your bottom line if you have too much of it. The longer you hold onto a product, the more its value goes down.

Here are a few ways to minimize your on-hand inventory:

-

Use the ABC classification from the previous step. Prioritize restocking your A items since they have the highest turnover and value.

-

Figure out if smaller order sizes are an option with your suppliers. You’ll also want to consider if this means you’ll miss out on bulk discounts, and whether the ultimate value is worth it.

-

Use an inventory management tool to forecast so you can better predict what you’ll need to have in stock based on demand trends, seasons, and your company’s performance.

5. Set reorder points and stay on top of them

Reorder points, also called ROPs, are a fancy way to say “the perfect time to order more products.” If you choose to calculate your reorder points, the best way to make sure they’re accurate is to calculate the reorder point for every variation of every item you sell.

Say you’re selling a sweater that comes in different patterns and sizes. You’ll need to run through the formula for every combination. In its simplest form, the reorder point formula is your lead time demand plus your safety stock.

Going into it a bit further, there are several lower-level calculations that make up your lead time demand and safety stock. For example, your lead time demand is your average daily usage times your lead time. And your average daily usage is the number of orders during a specific period, divided by the number of days in that period.

But once you have a solid grasp—and solid calculations—of the reorder points for all of your stock, your wholesale inventory management process is one step closer to being smoother and more optimized.

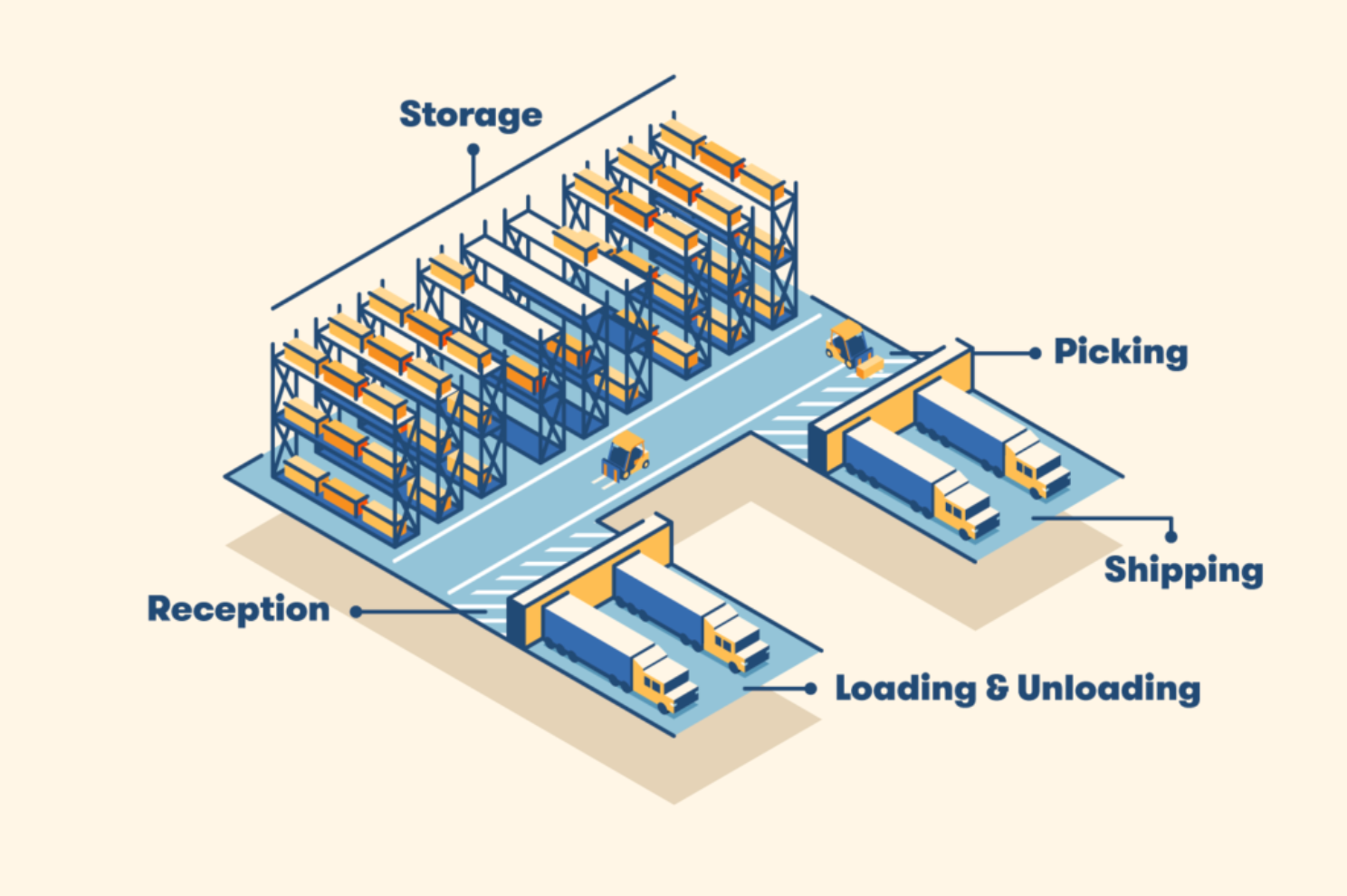

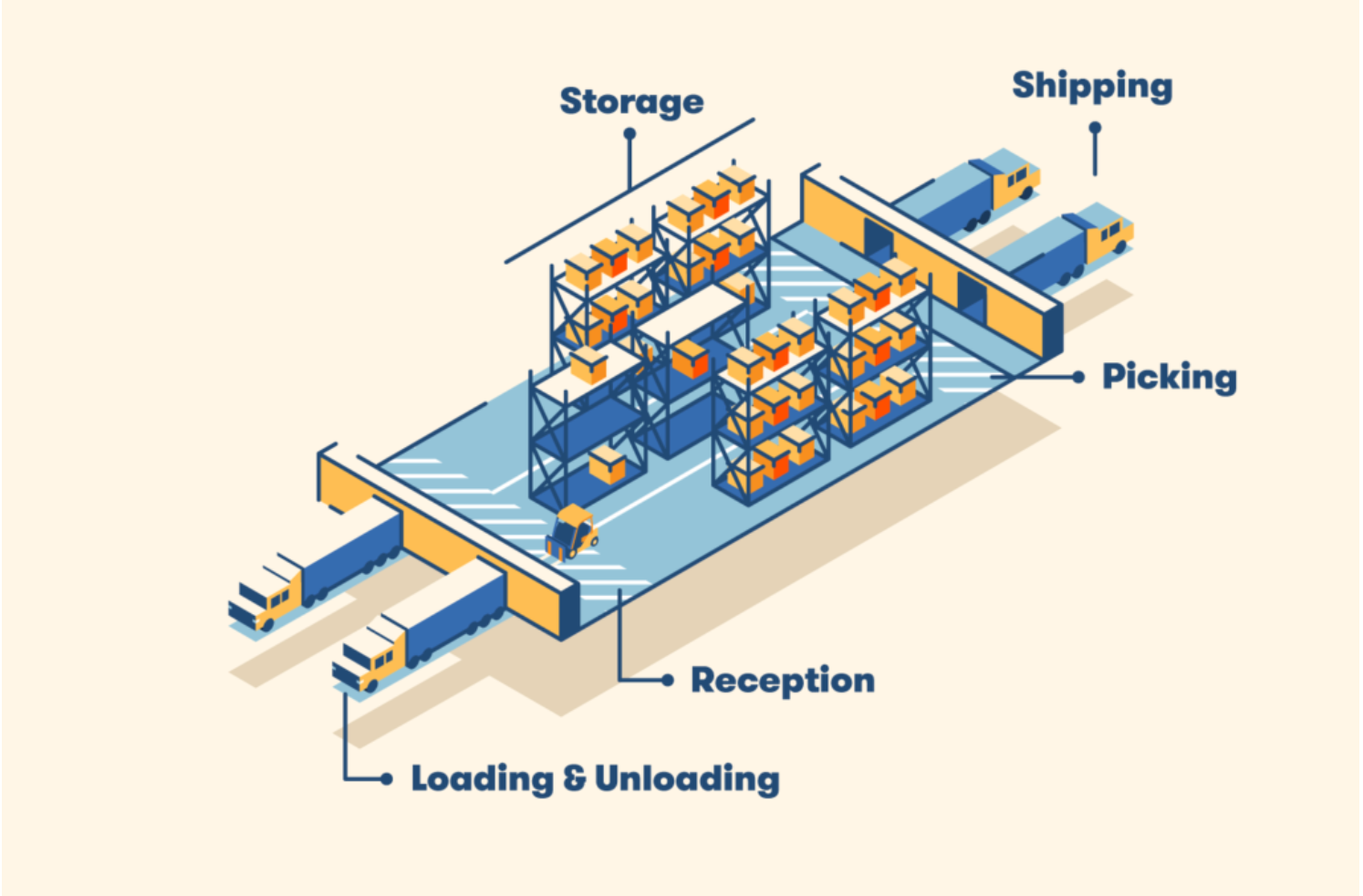

6. Optimize your warehouse’s layout

When it comes to effective inventory management techniques, the warehouse’s layout is often overlooked.

But it can make a surprisingly big difference for your team’s ability to pick and pack and get things shipped as quickly as possible.

For example, consider the three top layout designs and how they can help supercharge your inventory management and product delivery processes: U-shape, I-shape, and L-shape.

Here’s the U-shape:

Here’s the I-shape:

You can also keep some of these warehouse layout and design tips in mind:

-

When you’re planning, make a map that includes everything, even things like your offices and doors.

-

Place your bestselling items close to your picking and packing areas so they can move through easily.

-

Keep your picking area inside or next to your storage area so your team has easy access to everything.

-

Keep the packing and shipping areas separate from the rest of the warehouse to maximize the flow of traffic.

-

Test everything out before you finalize any changes. Do a walkthrough, including using equipment like forklifts.

Finding your ideal wholesale inventory management process

There are loads of inventory management examples out there and a virtually infinite way to get the job done well. It’s all a matter of experimenting and testing out different methods and solutions until you find what works best for your business.

Using Excel spreadsheets and doing things manually can certainly work, but beware of when your business hits a point where it’s time to scale up. This is an ideal time to switch to a holistic, tech-driven wholesale inventory management system.

When you have the tools to help do the legwork for you, you’ll have more time to spend making the important business growth decisions that only you can make.

Wholesale inventory management FAQ

What is wholesale inventory management?

Wholesale inventory management refers to managing your store, acquisition, and ordering for resale of products. With this system, you can keep the right levels of stock, balance customer demands while keeping costs down, and create a more efficient supply chain.

What are the 4 types of inventory management?

Four popular types of inventory management include:

-

Just-in-time (JIT) inventory management: Focuses on minimizing stock in hand to reduce carrying costs and ordering stock just as it’s needed.

-

Perpetual inventory management: A real-time tracking system that updates inventory after every transaction.

-

Periodic inventory management: Involves regular, scheduled counts of merchandise.

-

Lean inventory management: Focuses on streamlining inventory, reducing waste, and holding only what’s necessary to minimize costs and improve efficiency.

Why is wholesale inventory management important for wholesalers?

Wholesale inventory management helps wholesalers keep a balance between excess inventory and stock shortages, preventing profit losses and ensuring customer satisfaction. Managing inventory efficiently boosts cash flow, reduces storage costs, prevents perishables from spoiling, and allows you to plan and forecast based on trends in demand.